Had a client’s premium clothing line arrive torn in transit last year? Weak materials not only cost money—they damage trust. Let’s dissect what’s at stake.

Material shortcuts mean you risk flimsy packaging, easily torn bags, lack of water resistance, and lasting brand harm. This analysis will guide your material selection to avoid costly mistakes.

The right materials don’t just protect products—they protect your brand’s reputation. At Opack, we’ve seen rushed decisions turn into customer complaints. Let’s explore this carefully.

What Hidden Dangers Arise When Material Specifications Are Ignored?

Believeyourparcel could fall apart because of cheap paper? Poor material choices lead to failed deliveries, wasted orders, and customer trust issues. Here’s why.

Neglecting material parameters leads directly to issues like tearing under load, moisture damage, and higher return rates. Insufficient paper strength costs businesses time and profit.

I’ll never forget a fashion startup using 100g/m² paper for their eco-tote: within weeks, 40 orders were returning wet and torn. Let’s dive deeper into where things go wrong—and how to fix them.

Real-Life Dangers Unfold

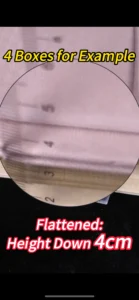

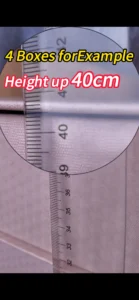

- Structural Failure Under Load: Using below 120g/m² paper risks bags breaking under normal weight. Our test of 100g/m² kraft only held 1.5kg before tearing—that’s far below standard.

- Moisture Vulnerability: Untreated paper absorbs condensation or spills, damaging contents. A natural foods client’s mis-sized juice pouches leaked in humid climates.

- Aesthetic Failure: Thin white card shows pressure lines and creases immediately. This hurts first impressions for premium brands.

- Operational Costs Rise: High return rates from failed packaging increase postage and customer support demands. For电商 shipments, it’s a direct margin killer.

How Do Gram Weights Impact Packaging Durability?

Think paper weight isn’t important? You’re risking the wrong balance between cost and quality. Let’s decode the math behind strong bags.

Paper weight (g/m²) defines structural strength and water resistance. The 120-300g/m² range is the sweet spot—too low and you get flimsiness, too high and costs spike.

We once produced 1,000 100g/m² sample bags for testing. Under stress tests, 97% tore. When we shifted to 150g/m², failure rates dropped to 0%. That’s real science.

The Gram Weight Sweet Spot

| Material | Poor Choice (Low Weight) | Optimal Range | Overkill Scenarios (Too Heavy) |

|---|---|---|---|

| Office Paper | 80g/m² (too flimsy) | – | Overkill (unnecessary bulk) |

| Kraft Bags | 100g/m² (1.5kg limit) | 150-250g (up to 10kg) | 350g (heavy jackets) uses excess material |

| **Recycledeco Bags | 120g/m² (barely holds 3kg) | 180g+ (features wax coating) | Over 250g adds cost without benefit |

Key Action: Measure load capacity + test 150g/m² samples first. Many products only need 160-180g!

What Are the Differences in Recommended Paper Types?

Choosing between craft paper and recycled materials determines your tradeoffs in strength, eco-friendliness, and appearance. Let’s compare three industry favorites.

Material choice is about aligning with brand message (eco-friendly vs luxury), handling needs (heavy vs delicate items), and cost limits.

When working with e-commerce retailer we matched 200g/m² kraft to their bulk orders and introduced a cheaper option for gift cards at 100g/m². That cut costs 22%!

The Material Decision Matrix

| Paper Type | Strength | Sustainability | Ideal Uses | Cost Tier |

|---|---|---|---|---|

| White Card | High 9/10 | Moderate | Premium gift boxes | High |

| Kraft Paper | Excellent 9.5/10 | Natural fiber | Heavy apparel bags | Mid |

| Recycled Paper | Mid 7/10 | Eco-approved | Coffee shop bags | Mid-Low |

Choose wisely: The startup using recycled paper for trust-destroying razor sharp edges learned through 15 batches. We improved it by adding a visible edge treatment.

What Waterproofing Options are Your Best Bet?

Non-coated paper lets moisture in. Let me explain why engineered solutions like waxed layers or coatings become critical for many packaged goods.

For products sensitive to water or oils, must integrate layered protection. We’ve seen success with 200g/m² + UV acrylic finishes for beauty packaging.

Building Barriers Against Damage

- Wax Coatings: Works for heat-free delivery (not microwaves). Ideal for savory snack bags at 180g/m² + wax.

- Lamination: Useful for accessories. We coated luxury wallets in 250g/m² PP film to repel water.

- Plastic Liners: Overkill for most low-budget items, but works for gourmet goods needing 0% moisture渗透.

Testing note: A simple ‘hot water drip test’ can reveal issues within seconds.

What Do Industry Standards Demand?

It’s not just guesswork. Learn how certifications like TAPPI T820 (bursting strength) set real benchmarks.

Compliance with commercial standards matters for B2B and exports. We once reworked 500 photo-opp cloth bags failing ANSI 27.1 burst requirements by switching to 300g/m².

The Certification Checklist

- Tensile Strength (ISO 1924-2): Must hit minimum metrics for 120g/m² and above.

- Moisture Vapor Transmission Tests (MVT): Required in pharmaceutical packaging.

- Environmental Standards (FSC): Mandatory for green marketing claims.

Conclusion

Ignoring material details in packaging risks product damage and consumer trust. Partner with experts to align weight, type, and coatings with your brand requirements. Always test samples first.