How Can Small Businesses Choose Cost-Effective Packaging Solutions Without Sacrificing Quality?

I’ve seen countless small business owners struggle with packaging decisions. They want professional presentation but fear the high minimums and costs typically associated with custom packaging. This dilemma affects their brand image and budget.

Small businesses can achieve professional packaging by starting with basic customized options like printed boxes or bags with lower minimum order quantities, choosing versatile designs that work across product lines, and gradually scaling up as they grow. Finding the right supplier who offers flexibility is crucial.

When I first started in the packaging industry, I assumed custom solutions were only viable for large corporations. I quickly discovered this wasn’t true. Let me share what I’ve learned about creating impressive packaging solutions specifically designed for small business needs.

What Are the Most Cost-Effective Packaging Options for Small Businesses?

I’ve watched small business owners become overwhelmed by minimum order requirements. They end up settling for generic packaging that fails to represent their brand, missing a crucial marketing opportunity and customer connection point.

The most cost-effective packaging options for small businesses include digitally printed folding boxes, kraft paper bags with custom printing, versatile tissue paper, and sticker/label customization of standard packaging. These options offer professional appearance with lower minimum quantities and investment.

After years of working with businesses of all sizes, I’ve developed specialized approaches for small businesses that deliver maximum impact without excessive costs. Let me explain how we make quality packaging accessible.

Smart Strategies for Small Business Packaging

The packaging landscape has transformed dramatically in recent years, particularly for small businesses. When I first started Opack Production, minimum order quantities (MOQs) were prohibitively high for smaller companies. Today, we specifically cater to small business needs with MOQs as low as 500 pieces for gift boxes and 1000 pieces for shopping bags.

Digital printing technology has been the game-changer in this space. Unlike traditional offset printing with high setup costs and large minimum runs, digital printing offers:

- Lower setup fees and faster turnaround times

- Cost-effective short runs without quality compromise

- Full-color capabilities without price increases per color

- The ability to print variable data (different designs in the same run)

I’ve helped numerous small businesses leverage these advantages. For example, one boutique cosmetics brand I worked with needed packaging for their initial product launch but had limited capital. We created digitally printed folding boxes that looked premium but required minimal investment, allowing them to allocate more resources to product development and marketing.

| Packaging Type | Traditional MOQ | Our Small Business MOQ | Cost Saving |

|---|---|---|---|

| Gift Boxes | 1000-3000 pieces | 500 pieces | 50-80% |

| Shopping Bags | 3000-5000 pieces | 1000 pieces | 60-80% |

| Custom Tissue | 10000 sheets | 2000 sheets | 70-80% |

| Printed Ribbons | 5000 meters | 1000 meters | 65-80% |

Another effective strategy we recommend is choosing versatile packaging designs that work across multiple products. Rather than creating unique packaging for each item, we help small businesses develop flexible solutions that accommodate various products while maintaining brand consistency. This approach reduces overall costs while maximizing the professional appearance of your entire product line.

For businesses just starting out, we often recommend a hybrid approach: using standard packaging enhanced with custom elements. This might include stock boxes with custom printed labels, standard bags with beautifully designed hang tags, or plain kraft packaging elevated with custom stamps or stickers. These methods create a professional, branded look without requiring full custom production.

How Should Small Businesses Balance Quality and Budget When Selecting Materials?

I’ve seen small business owners make costly mistakes when selecting packaging materials. They either overspend on premium options they can’t sustain or choose materials too flimsy to protect their products, resulting in damage claims and lost customers.

Small businesses should balance quality and budget by selecting mid-grade materials with strategic premium touches, considering product protection requirements first, then adding brand-appropriate finishes selectively. Understanding material alternatives that mimic premium looks at lower costs is essential.

Material selection represents one of the most impactful decisions in the packaging process. Through my years of experience, I’ve developed specific approaches to help small businesses navigate these choices effectively.

Smart Material Selection Strategies

In my experience, small businesses often assume they must choose between cheap, generic packaging or expensive, premium options. This false dichotomy leads to either brand image problems or unsustainable costs. The reality is much more nuanced.

When consulting with small business clients, I start by analyzing three critical factors:

- Product protection requirements

- Brand positioning and customer expectations

- Available budget and volume needs

This assessment helps identify the optimal material balance. For example, a jewelry company needs sufficient structural integrity to protect delicate items, materials that communicate premium value, all while managing startup costs. Rather than selecting the most expensive option for every element, we might recommend:

- Standard weight paperboard with premium coatings for boxes

- Mid-grade paper with selective spot UV highlights

- Strategic use of foil accents only on customer-facing elements

This targeted approach achieves the luxury feel without unnecessary expenses on elements customers don’t notice or value.

| Material Category | Budget Option | Mid-Range Option | Premium Option | Recommendation |

|---|---|---|---|---|

| Box Board | 250gsm white card | 300gsm coated board | 350gsm specialty board | 300gsm with premium finish |

| Bags | Standard kraft | Colored kraft | Specialty textured | Colored kraft with upscale handles |

| Tissue | Plain white | Printed 1-color | Full-color custom | Plain with custom stamp |

| Ribbons | Polyester | Satin | Grosgrain/Velvet | Satin with custom printing |

I’ve found that small businesses benefit tremendously from understanding material alternatives that create similar impressions at different price points. For instance:

- Embossing can create texture and dimension without expensive materials

- Soft-touch coating gives a luxurious feel at a fraction of premium paper costs

- Digital metallic inks can simulate foil stamping at lower production costs

- Textured papers often deliver more brand impact than thicker standard papers

One of my favorite success stories involves a small gourmet food company that needed gift packaging for specialty items. Rather than using expensive rigid boxes, we designed a clever folding structure using mid-weight paperboard with a soft-touch coating and minimal hot stamping on the closure. The result looked and felt premium but cost about 60% less than traditional luxury packaging.

For businesses concerned about sustainability, we offer various eco-friendly materials at different price points. Kraft papers, recycled boards, and biodegradable finishes can be combined to create environmentally responsible packaging that aligns with both brand values and budget constraints.

What Custom Packaging Options Have the Lowest Minimum Order Quantities?

I’ve watched small business owners resign themselves to generic packaging because they assume custom options require enormous orders. They miss opportunities to strengthen their brand because they don’t know which customization options have lower barriers to entry.

Custom packaging options with the lowest minimum order quantities include digitally printed folding cartons (500 pieces), branded paper bags (1000 pieces), custom labels and stickers (250-500 pieces), and hand-stamped or embellished standard packaging (no minimum). These options provide brand differentiation with minimal inventory commitment.

After working with hundreds of small businesses, I’ve developed specialized knowledge about which customization options are most accessible for companies with limited volume needs or startup budgets.

Accessible Customization Approaches

The packaging industry has traditionally catered to large-scale production, but at Opack, we’ve intentionally developed solutions for smaller businesses. I’ve found that certain customization methods inherently support lower minimum quantities without sacrificing quality or brand impact.

Digital printing stands out as the most transformative technology for small business packaging. Unlike traditional printing methods that require plates and extensive setup, digital printing enables:

- Custom folding cartons with minimums as low as 500 pieces

- Full-color shopping bags starting at 1000 pieces

- Personalized mailers and shipping boxes from 500 units

- Custom tissue paper from 2000 sheets

One boutique skincare brand I worked with leveraged digital printing to create separate packaging for five different products, ordering just 500 units of each. With traditional methods, this would have been prohibitively expensive due to multiple setup fees and minimum runs.

| Customization Method | Our Minimum Order | Industry Standard | Best Used For |

|---|---|---|---|

| Digital Printed Boxes | 500 pieces | 1000-3000 pieces | Product packaging, gift boxes |

| Custom Paper Bags | 1000 pieces | 3000-5000 pieces | Retail, e-commerce |

| Custom Stickers/Labels | 250-500 pieces | 1000+ pieces | Enhancing stock packaging |

| Custom Tissue Paper | 2000 sheets | 10000+ sheets | Void fill, gift wrapping |

| Ribbon Printing | 1000 meters | 5000+ meters | Gift packaging, luxury touches |

For businesses needing even smaller quantities, we recommend several hybrid approaches:

- Stock packaging with custom labels or stickers

- Standard boxes with custom printed belly bands

- Plain bags with custom hang tags or handles

- Basic packaging with custom rubber stamps

- Standard boxes with window cutouts showcasing custom inserts

These methods create a custom look without requiring full custom production. I recently helped an artisanal chocolate maker who needed distinctive packaging but could only order 250 units initially. We selected elegant stock boxes and created custom printed inserts and labels, achieving a premium branded appearance at a fraction of the cost of fully custom packaging.

Another effective strategy for very small orders is hand-applied customization. Techniques like wax seals, hand-stamping, custom stickers, and decorative tags can transform standard packaging into something special and brand-specific. While more labor-intensive, these methods eliminate minimum order constraints entirely and can be particularly appropriate for handcrafted or artisanal products.

How Can Small Businesses Create Packaging That Scales With Their Growth?

I’ve seen small businesses make costly mistakes with packaging that can’t evolve with their needs. They either invest in designs that become impractical at larger volumes or choose temporary solutions that must be completely replaced as they grow, losing brand continuity.

Small businesses can create scalable packaging by designing modular systems with consistent brand elements, choosing structures that work across various production methods, planning for future product line expansions, and selecting suppliers experienced in supporting growing companies through various business stages.

Throughout my career in packaging, I’ve helped many businesses evolve from startup to established brand. This experience has taught me valuable lessons about designing for scalability that I’m excited to share.

Designing Packaging Systems That Grow With You

When I work with small businesses, I always encourage them to think about their packaging as a system rather than individual pieces. This approach creates a foundation that can evolve and expand without requiring complete redesigns at each growth stage.

A packaging system approach includes several key components:

- Consistent visual identity elements (logos, colors, patterns)

- Modular design components that work across product lines

- Structures that can be produced via different methods at different scales

- Documentation of specifications for consistent reproduction

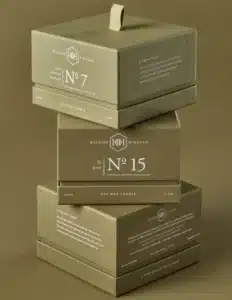

One of my favorite success stories involves a specialty tea company that started with just three products and limited packaging budget. We created a design system with consistent branding elements but different structural formats based on product requirements. As they grew from 500-unit orders to 10,000+, the visual brand remained consistent even as production methods evolved from digital to offset printing.

| Growth Stage | Recommended Approach | Future-Proofing Strategy |

|---|---|---|

| Startup (< 1000 units) | Digital printing, hybrid customization | Design for easy transition to offset |

| Early Growth (1000-5000) | Mix of digital and offset, standard structures | Maintain consistent brand elements |

| Established (5000+) | Fully custom structures, specialized finishes | Develop packaging family approach |

I recommend creating a clear brand style guide specifically for packaging early in your business journey. This document should include:

- Color specifications (in both Pantone and CMYK values)

- Typography guidelines and font selections

- Pattern and graphic element specifications

- Photography/imagery style guidance

- Voice/tone for packaging copy

This documentation ensures consistency as you transition between production methods, quantities, and even different suppliers. I’ve seen this approach save businesses significant costs by eliminating the need to completely rebuild artwork files when scaling up.

Another important consideration is designing structures that can be produced using different methods. For example, a folding carton design that works with both digital and offset printing allows seamless transitions as order quantities increase. Similarly, choosing designs that can be either hand-assembled or machine-glued provides flexibility as production volumes grow.

Working with suppliers who understand growth trajectories is invaluable. At Opack, we specifically help clients plan packaging strategies that accommodate different stages of business growth. This might include starting with higher-cost-per-unit but lower minimum options, then transitioning to more economical production methods as volumes increase.

How Do Small Businesses Benefit from Professional Package Design Services?

I’ve watched small businesses struggle with DIY packaging design that looks amateur and undermines their product quality. They try to save money upfront but lose sales due to packaging that fails to communicate value or attract customer attention.

Small businesses benefit from professional package design through enhanced shelf presence that drives sales, expert knowledge of production requirements that prevents costly mistakes, and strategic consultation on materials and structures that optimize both protection and presentation within budget constraints.

Having worked with designers throughout my career in packaging, I’ve developed a deep appreciation for the value they bring to small businesses. Let me explain how professional design services can transform your packaging strategy.

The Strategic Value of Professional Design

When small business owners handle their own packaging design, they typically focus solely on aesthetics. Professional designers, however, approach packaging as a strategic business tool that must accomplish multiple objectives simultaneously:

- Attract customer attention and communicate brand values

- Protect and present the product effectively

- Function practically throughout the supply chain

- Consider cost and production efficiency

- Drive purchasing decisions at the point of sale

At Opack, our design team combines creative talent with technical expertise in materials, printing processes, and structural engineering. This combination prevents costly mistakes that often occur when design is divorced from production knowledge.

I remember working with a small cosmetics company that had previously ordered packaging designed by a graphic designer with no packaging experience. Despite beautiful artwork, the design had required expensive special dies, included colors that couldn’t be accurately reproduced on their chosen material, and featured structural elements that frequently failed during shipping. Our team redesigned their packaging to be both visually appealing and practically executable, actually reducing their overall costs.

| Design Service | Small Business Benefit | Cost Considerations |

|---|---|---|

| Structural Design | Optimized protection, efficient material usage | Prevents damage claims and waste |

| Graphic Design | Professional brand presentation | Elevates perceived product value |

| Production Consultation | Material and process recommendations | Avoids costly production mistakes |

| Packaging System Development | Consistent brand experience | Creates efficiency across product lines |

Professional designers also bring specialized knowledge about consumer psychology and purchasing behavior. They understand how elements like color, typography, and composition influence buying decisions in different retail environments. This expertise can dramatically impact sales performance, particularly for products sold in competitive retail spaces.

For businesses concerned about design costs, I recommend viewing professional design as an investment rather than an expense. The cost difference between amateur and professional design is typically recovered quickly through:

- Increased sales due to improved shelf presence

- Higher price points supported by premium presentation

- Reduced damages and returns from proper structural design

- Production savings from optimized material usage and printing specifications

At Opack, we offer design services specifically scaled for small businesses, including options with our manufacturing services that make professional design more accessible. Our multilingual design team also eliminates communication barriers, ensuring your packaging vision is accurately translated into production specifications without misunderstandings.

For businesses with existing brand assets but limited packaging experience, we offer consultation services that bridge the gap between general branding and packaging-specific requirements. This approach maintains brand consistency while ensuring packaging functionality.

Get Premium Finishing For Your Designs At OPACK

Looking for a reliable and affordable supplier? OPACK is your trusted partner for creating stunning designs that leave a lasting impression and add elegance and sophistication to your packaging. Contact us now to order.