Folding gift boxxes](https://www.opack.com/benefits-of-environmentally-friendly-boxes-for-sustainable-packaging/) and customize folding gift boxes are essential packaging solutions that combine aesthetics with functionality. Whether you’re a business owner looking to elevate your brand or a creative enthusiast exploring DIY options, transforming a flat design into a beautiful three-dimensional box is both satisfying and practical.

The journey from a simple paper template to a stunning folding gift box involves selecting the right design structure, choosing appropriate materials, incorporating brand elements, creating prototypes, and optimizing for production—all while ensuring the finished product perfectly showcases your brand or gift.

When I first entered the packaging industry, I was amazed by how a simple sheet of paper could transform into an elegant container. Today, I’ll guide you through this fascinating process, sharing professional insights from my years of experience helping brands create memorable packaging solutions.

What Are the Key Design Options for Custom Folding Gift Boxes?

Many business owners make the mistake of choosing standard box designs without exploring the full range of options available. This limits their brand’s potential to stand out in a crowded marketplace.

Folding gift boxxes](https://www.opack.com/benefits-of-environmentally-friendly-boxes-for-sustainable-packaging/) come in various structural designs including magnetic closure, side-foldable, origami-style, auto-lock bottom, and rigid options—each offering different benefits for stability, user experience, and brand presentation while accommodating diverse product protection needs.

Exploring Popular Folding Box Structures

The structure of your folding gift box dramatically impacts both its functionality and visual appeal. Let me walk you through the most effective designs I’ve implemented for various clients:

Magnetic Closure Boxes: These premium options feature embedded magnets that create a satisfying "snap" when closed. They offer excellent reusability and create an upscale unboxing experience. I’ve found these particularly effective for luxury brands where the packaging needs to reinforce a premium positioning.

Side-Foldable Designs: These space-saving structures can be shipped flat and assembled when needed. This design significantly reduces shipping and storage costs—a crucial consideration for businesses managing inventory costs.

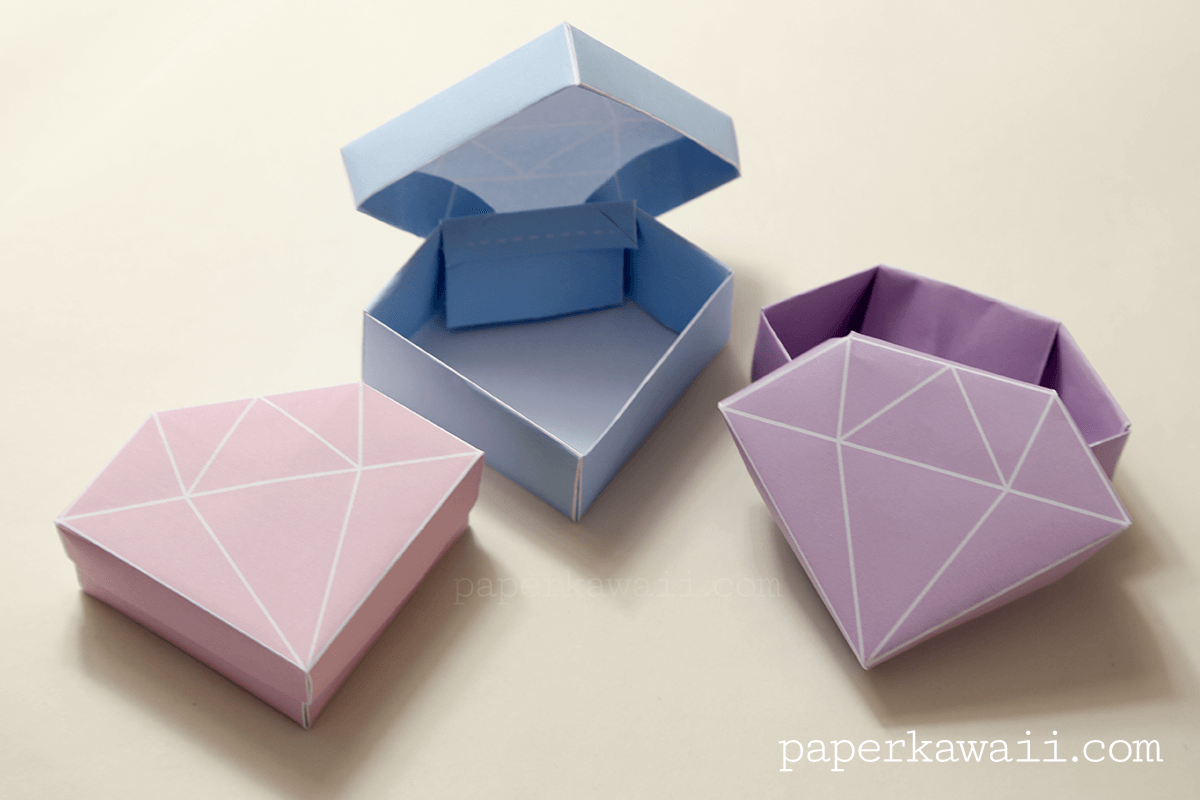

Origami-Style Boxes: Drawing inspiration from Japanese paper-folding techniques, these intricate designs require no adhesives and can create stunning geometric patterns. They’re perfect for brands looking to create a memorable, artistic impression.

Auto-Lock Bottom Boxes: Featuring self-locking mechanisms, these boxes assemble quickly without tape or glue. This design saves assembly time while ensuring secure closure—ideal for production efficiency.

Rigid Folding Boxes: These hybrid designs combine the strength of rigid boxes with the convenience of folding structures, offering exceptional durability while maintaining some collapsibility.

| Box Structure | Best For | Key Advantages |

|---|---|---|

| Magnetic Closure | Luxury items, gifts | Premium feel, reusable |

| Side-Foldable | E-commerce, shipping | Space-saving, economical |

| Origami-Style | Artistic brands, light items | Unique design, no adhesives |

| Auto-Lock Bottom | Production efficiency | Quick assembly, secure closure |

| Rigid Folding | Heavy or fragile items | Extra protection, premium appearance |

How Do You Choose the Right Templates and Tools?

Starting with the wrong template or inappropriate tools can lead to wasted materials, inconsistent results, and frustrated customers. Professional templates ensure precision and repeatability.

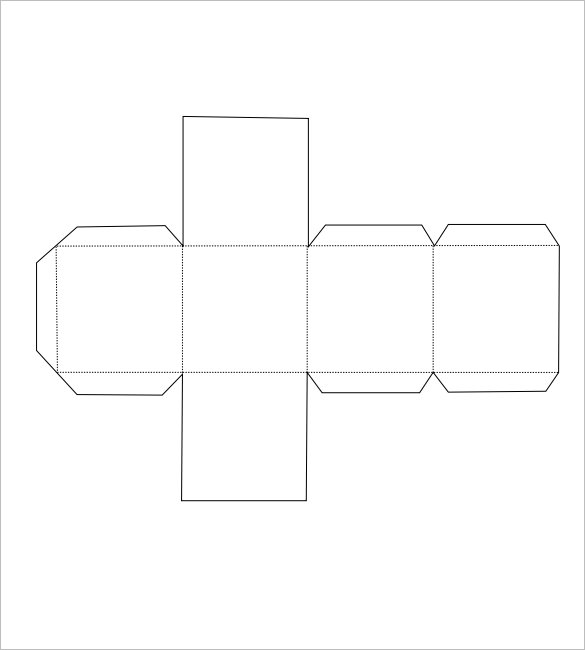

Selecting appropriate templates for your folding gift boxes begins with identifying the right box style and dimensions for your product, then using either free online resources or professional design software to create precise patterns that can be accurately replicated in production.

Finding and Using Professional Templates

In my professional experience, templates are the foundation of successful box design. Here’s how I approach template selection:

Free Online Resources: Websites like Homemade-Gifts-Made-Easy and The Spruce Crafts offer printable templates for various box styles. These are excellent starting points for small businesses or prototype testing. I often recommend these to clients who need quick proof-of-concept models.

Professional Design Software: For customized dimensions or high-volume production, professional tools like Adobe Illustrator, BoxMaker, or Packly allow for precise adjustments to fit your specific products. These programs create industry-standard dieline files that manufacturers can work with directly.

Scaling Considerations: When selecting templates, consider not just the current size needs but future scaling. I always advise clients to think about their complete product line and create template systems that can be adjusted proportionally for different product sizes.

Essential Measurements: Accurate internal dimensions are critical—always measure your product plus adequate padding (typically 0.125"-0.25" on all sides). Then calculate the external dimensions based on material thickness.

Tools for Precision and Efficiency

The right tools elevate your folding gift box from amateur to professional quality:

- Scoring Tools: For clean, precise folds on thicker materials

- Bone Folders: Create sharp creases without damaging paper fibers

- Steel Rulers: Essential for straight cutting lines

- Cutting Mats: Protect work surfaces and improve cutting accuracy

- Die-Cutting Machines: For small-batch production with consistent results

What’s the Step-by-Step Process for Creating Folding Gift Boxes?

Following a systematic assembly process ensures consistent quality and prevents costly mistakes. Skipping steps often leads to structural weaknesses or aesthetic flaws.

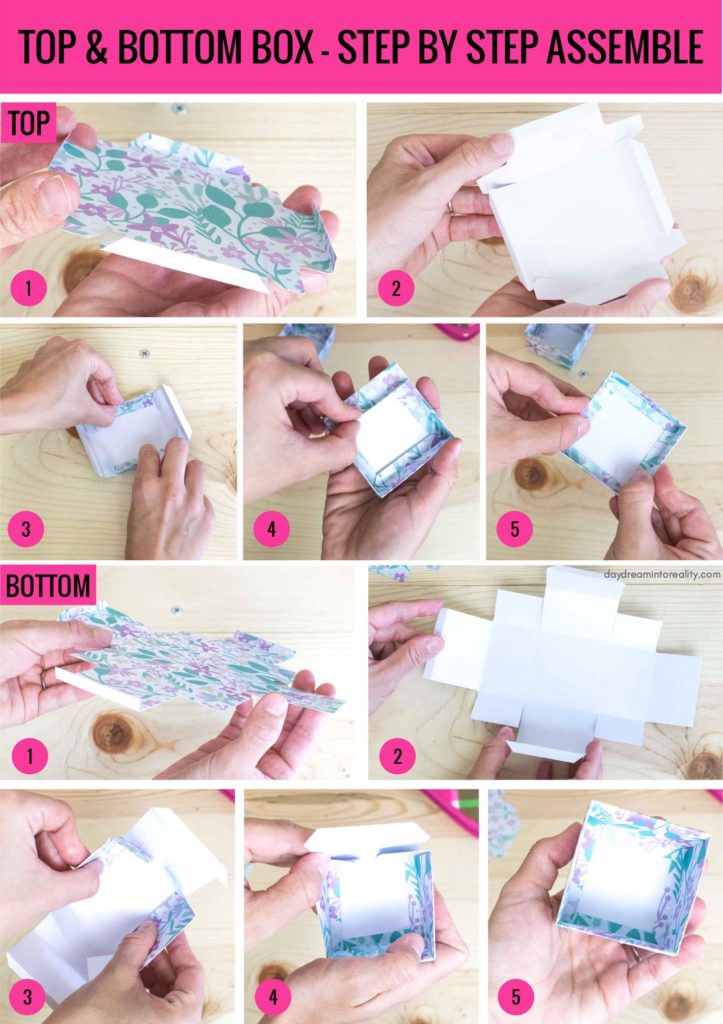

Creating professional folding gift boxes follows a systematic process: designing the dieline, preparing the template, cutting the material, scoring fold lines, creating creases, applying adhesives if needed, assembling the structure, and adding finishing touches like branding elements.

The Professional Assembly Process

Drawing from my experience overseeing countless packaging productions, here’s the refined process I recommend:

1. Preparation Phase

Start by marking your template onto the chosen material. Use light pencil marks or non-permanent markers that won’t show on the finished product. Ensure you’re working on a clean, flat surface to prevent material contamination.

2. Cutting Phase

Cut along the outer edges of your template using appropriate tools for your material thickness. For cardstock, precision scissors or craft knives work well. For thicker materials like corrugated cardboard, use stronger cutting tools. Always cut away from yourself and maintain consistent pressure for clean edges.

3. Scoring Phase

Scoring creates controlled fold lines that result in clean, professional creases. Run a scoring tool along all fold lines while applying gentle pressure against a steel ruler. This compresses the fibers without cutting through, allowing for precise folds.

4. Folding Sequence

Follow a logical sequence when folding, typically starting with the main structure before moving to tabs and closures. This prevents awkward positioning later in the assembly. I always fold "with the grain" of the material when possible for cleaner results.

5. Adhesive Application (if needed)

Apply adhesives sparingly and precisely to joining tabs. Different materials require different adhesives—PVA glue works well for paper and cardstock, while hot melt glues or specialized adhesives may be necessary for coated or synthetic materials.

6. Quality Check

Before finalizing your box, check all corners and seams for alignment and security. Test the opening and closing mechanism multiple times to ensure smooth operation and proper fit.

How Do You Select the Right Materials for Folding Gift Boxes?

Using inappropriate materials leads to boxes that fail during shipping, disappoint customers, or don’t align with brand values. Material selection affects both performance and perception.

Selecting materials for folding gift boxes involves balancing functional requirements like durability and weight with aesthetic considerations like texture and printability while considering environmental factors and cost constraints to achieve the optimal balance for your specific application.

Material Options and Their Applications

Through years of material testing and client consultations, I’ve developed clear guidelines for material selection:

Corrugated Cardboard: Offering excellent strength-to-weight ratio, corrugated cardboard is ideal for shipping boxes or products needing extra protection. Available in various flute sizes (E-flute for retail packaging, B-flute for shipping boxes), it balances protection with weight considerations.

Kraft Paper: This versatile material offers natural aesthetics with good durability. Its natural brown finish conveys eco-friendliness, or it can be bleached white for a cleaner look. I often recommend Kraft for brands with environmental values or rustic aesthetics.

Cardstock: Available in various weights (typically 250-350 gsm), cardstock offers good rigidity for smaller boxes while taking well to detailed printing. It’s excellent for retail packaging where visual presentation is paramount.

Specialty Papers: For premium applications, specialty papers like linen-textured, metallic, or handmade papers create distinctive tactile experiences that enhance perceived value.

Coated Papers: These provide superior print reproduction and protection against moisture or scuffing. Options include glossy, matte, or satin finishes, each creating different visual and tactile impressions.

| Material | Durability | Printability | Eco-Friendliness | Cost |

|---|---|---|---|---|

| Corrugated Cardboard | High | Moderate | Good | Low-Moderate |

| Kraft Paper | Moderate | Good | Excellent | Low |

| Cardstock | Moderate | Excellent | Good | Moderate |

| Specialty Papers | Varies | Excellent | Varies | High |

| Coated Papers | High | Superior | Moderate | Moderate-High |

How Can You Customize Folding Gift Boxes for Brand Impact?

Generic packaging fails to leverage the powerful branding opportunity that custom boxes provide. Thoughtful customization transforms packaging from a mere container into a brand ambassador.

Customizing folding gift boxes for maximum brand impact involves strategic design decisions regarding printing techniques, color applications, texture enhancements, structural innovations, and finishing treatments that collectively communicate your brand identity while creating memorable customer experiences.

Advanced Customization Techniques

From my experience working with premium brands, these customization approaches consistently deliver exceptional results:

Printing Techniques:

- Offset Printing: Delivers exceptional color accuracy and detail, ideal for photographic imagery or complex designs.

- Digital Printing: Perfect for short runs or variable data printing where each box may feature unique elements.

- Flexographic Printing: Cost-effective for larger runs with simpler designs, especially on corrugated materials.

- Screen Printing: Creates vibrant, durable ink deposits, excellent for bold colors or metallics.

Surface Enhancements:

- Hot Foil Stamping: Adds metallic elements that catch light and create premium impressions.

- Embossing/Debossing: Creates tactile dimension that encourages customers to interact with your packaging.

- Spot UV: Applies selective glossy coating to highlight specific design elements against matte backgrounds.

- Soft-Touch Lamination: Creates a velvety feel that suggests luxury and quality.

Structural Customization:

- Custom Windows: Showcase product visibility while protecting contents.

- Integrated Inserts: Hold products securely in place while enhancing presentation.

- Specialty Closures: Magnetic snaps, ribbon ties, or interlocking tabs create memorable unboxing experiences.

- Unique Shapes: Die-cut windows or edges that reflect product themes or brand identity.

What Testing Procedures Ensure Your Folding Gift Box Design Works?

Skipping the testing phase can lead to production disasters, wasted materials, and damaged customer relationships. Thorough testing prevents costly mistakes.

Testing folding gift boxes involves creating physical prototypes, evaluating structural integrity, examining print quality, assessing user experience, and conducting shipping simulations to identify and resolve potential issues before committing to full production.

Professional Testing Protocol

Based on my experience overseeing quality control for packaging projects, here’s the testing protocol I recommend:

1. Prototype Evaluation

Create multiple prototypes using the actual production materials. Examine each for structural integrity, focusing on stress points like corners and closures. I typically recommend making at least three prototypes to account for material variations.

2. Fit Testing

Place your actual products inside the prototypes, checking for:

- Sufficient internal space

- Secure positioning without movement

- Easy insertion and removal

- Protection from impact or compression

3. Assembly Assessment

Time how long assembly takes and identify any challenging steps. If the box is difficult for your team to assemble, consider how this might affect production efficiency or customer experience for self-assembly options.

4. Print and Finish Quality

Examine all printed elements under various lighting conditions. Check for:

- Color accuracy and consistency

- Print registration

- Finish quality (lamination, coating, embossing)

- Barcode readability if applicable

5. Environmental Testing

Subject prototypes to environmental conditions they might encounter:

- Humidity resistance

- Temperature fluctuations

- Light exposure (for potential fading)

- Stacking pressure

6. Shipping Simulation

Perhaps most importantly, conduct realistic shipping tests:

- Package the box as you would for actual shipment

- Submit it to typical handling conditions

- Ship a sample to yourself via your standard shipping method

- Evaluate condition upon arrival

Get Premium Folding Gift Boxes from OPACK

Looking to bring your custom folding gift box design to life? At OPACK, we specialize in transforming concepts into stunning reality with our professional design services, premium materials, and state-of-the-art production facilities. Contact us to discuss your project and request samples of our exceptional work.

Conclusion

Creating folding gift boxes from design to reality involves understanding structural options, selecting appropriate templates and materials, following precise assembly processes, and implementing effective customization techniques. With the right approach, your custom boxes will not only protect your products but also become powerful brand ambassadors that enhance customer experience and drive business growth. Whether you’re making a simple prototype or scaling to mass production, these principles ensure your folding gift boxes achieve both functional and aesthetic excellence.