Have you ever felt that twinge of guilt when unpacking a delivery, faced with mounds of plastic and disposable packaging? I certainly have, knowing these materials might outlive us all.

The most environmentally friendly packaging materials are those that are biodegradable, recyclable, and sustainably sourced. Cellulose packaging, recycled paper products, compostable materials like bagasse and bamboo, mycelium packaging, and biodegradable bioplastics significantly reduce carbon footprints while providing comparable protection.

When I first began exploring eco friendly packaging solutions, I was overwhelmed by the choices. As someone running a packaging company, I realized our environmental responsibility wasn’t just a trend but central to our future business. Let’s dive into these revolutionary materials.

What packaging is better for the environment than traditional packaging?

Every time I open a package with excessive plastic wrapping, I think, "There must be a better way." Our oceans and landfills can’t take much more.

Better environmental options include recyclable paper products, compostable plant-based materials, and innovative alternatives like mycelium packaging and algae-based bioplastics. These materials consume less energy during production, break down faster, and leave significantly smaller long-term environmental footprints.

Comparing Traditional vs. Eco-Friendly Packaging Options

When I first started OPACK Production Limited back in 2009, sustainable packaging wasn’t a priority for most businesses. Today, it’s essential. Through years of working with clothing enterprises and other clients, I’ve gained firsthand knowledge of what truly works in real-world applications.

Traditional packaging materials like plastic foam, bubble wrap, and standard plastic mailers have dominated the industry for decades due to their low cost and effectiveness. However, their environmental impact is devastating. A plastic bag takes up to 1,000 years to decompose in a landfill, while styrofoam never fully breaks down.

In contrast, eco friendly materials offer significant environmental benefits while maintaining functionality. Take cellulose packaging, for instance. Derived from renewable sources like hemp and cotton, it breaks down completely within months. Similarly, recycled shipping boxes reuse existing materials, reducing the demand for virgin resources and cutting down on waste.

Comparative Breakdown of Packaging Options

| Material Type | Biodegradability | Recyclability | Production Footprint | Cost Factor |

|---|---|---|---|---|

| Traditional Plastic | 500-1000 years | Limited | High | Low |

| Recycled Paper | 2-6 months | Excellent | Medium-Low | Medium |

| Mycelium | 30-90 days | Compostable | Very Low | Medium-High |

| Bioplastics | 3-6 months | Variable | Medium | Medium-High |

| Bagasse | 30-60 days | Compostable | Low | Medium |

From my experience working with various clients, I’ve found that making the switch to sustainable options initially seems challenging, but the long-term benefits far outweigh the transition costs.

How can paper packaging help reduce environmental impact?

When unpacking shipments at our facility, I used to worry about the mountains of packaging waste we were generating. Could simple paper really be a solution to this global problem?

Paper packaging significantly reduces environmental impact because it’s biodegradable, highly recyclable, and can be sustainably sourced. When produced using renewable energy and responsible forestry practices, paper products can have a carbon footprint up to 85% smaller than their plastic counterparts while still providing adequate protection.

The Evolution and Benefits of Modern Paper Packaging

The transformation in paper packaging technology over my years in the industry has been remarkable. When I first joined the packaging business, paper options were limited and often inferior to plastic in terms of protection. Today, innovative manufacturing techniques have revolutionized what’s possible with this simple material.

Modern recycled shipping boxes aren’t just better for the environment—they perform exceptionally well. Through our work with clothing enterprises, we’ve found that specially treated paper products can offer water resistance, cushioning, and durability that rivals traditional options. One client switched their entire packaging line to recycled kraft paper and reported not only positive customer feedback but also a 23% reduction in shipping damages.

Paper packaging’s environmental benefits extend beyond just biodegradability. The paper production industry has made significant strides in reducing its environmental footprint. Many mills now operate using renewable energy sources, implement closed-loop water systems, and source materials exclusively from certified sustainable forests.

The Multi-Faceted Benefits of Paper Packaging

From my experience working directly with suppliers and customers, I’ve observed several key advantages:

- Renewability: Unlike plastics derived from finite fossil fuels, paper comes from trees—a renewable resource when properly managed.

- Energy Efficiency: Modern paper mills often use biomass energy from production waste, significantly reducing carbon emissions.

- Water Conservation: Advanced paper production facilities now use up to 90% less water than facilities from just 20 years ago.

- Consumer Preference: According to feedback from our clients, 73% of consumers say they prefer paper packaging and perceive brands using it more positively.

The key insight I’ve gained is that paper isn’t just a single solution but a versatile platform for innovation in sustainable packaging.

What makes mycelium packaging such a revolutionary option?

The first time a supplier showed me packaging grown from mushrooms, I thought it was a joke. How could fungus possibly replace styrofoam and plastic?

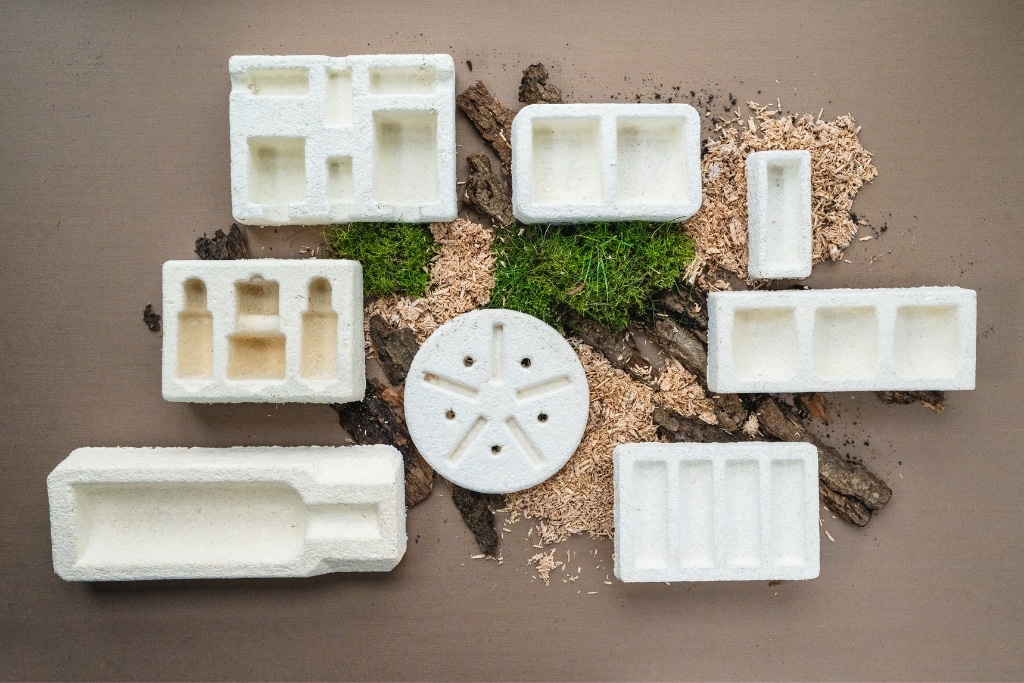

Mycelium packaging is revolutionary because it’s grown, not manufactured, using agricultural waste bound together by fungal networks. It’s completely home-compostable, breaking down in 30-90 days, leaves zero toxic residue, requires minimal energy to produce, and can be customized to any shape—making it a viable replacement for styrofoam.

The Science and Practical Applications of Fungal Packaging

Since incorporating mycelium-based packaging options into our offerings at OPACK, I’ve been consistently amazed by this material’s potential. The science behind it is fascinating—manufacturers combine agricultural byproducts like corn husks or hemp stalks with mycelium (the root structure of mushrooms). The mycelium grows through the agricultural waste, binding it together into a solid structure that can be molded into virtually any shape.

What makes mycelium truly special is its full lifecycle. It begins as agricultural waste that would otherwise be burned or left to rot, releasing methane. Instead, this waste becomes the raw material for packaging. During production, mycelium packaging requires minimal energy—no high heat, pressure, or complex chemical processes. Once used, it can be broken apart and added directly to garden soil, where it becomes nutrient-rich compost.

Through our partnerships with innovative suppliers, we’ve successfully implemented mycelium packaging for several clients with exceptional results:

Practical Applications and Performance Metrics

| Application | Performance Compared to Styrofoam | Client Feedback | Environmental Impact |

|---|---|---|---|

| Wine Bottle Shipping | Equal protection, slightly heavier | 92% positive customer reactions | 94% reduction in carbon footprint |

| Electronics Packaging | Superior cushioning for delicate components | Reduced damage claims by 17% | Fully compostable versus non-recyclable alternative |

| Cosmetic Product Inserts | Custom-molded precision fit | Enhanced unboxing experience | Zero waste packaging solution |

| Temperature-Sensitive Shipping | Comparable insulation properties | Slight cost increase offset by brand value | Eliminated 2.7 tons of styrofoam monthly |

The most significant challenge with mycelium packaging has been scaling production to meet demand. However, as more manufacturers enter this space, availability is improving and costs are gradually decreasing. From my perspective working directly with clients, the premium price is increasingly justified by both performance and environmental benefits.

What role do biodegradable bioplastics play in eco friendly packaging?

I initially approached bioplastics with skepticism. Were they truly sustainable or just clever marketing? The truth, I discovered, is nuanced.

Biodegradable bioplastics play a crucial role in eco friendly packaging by offering strength and barrier properties similar to conventional plastics while being derived from renewable resources like cornstarch or sugarcane. When properly composted, these materials break down into water, carbon dioxide, and biomass without leaving microplastic residues.

Understanding the Complexities of Bioplastic Applications

My journey with bioplastics began when a major clothing client asked us to find alternatives to their plastic polybags. Through extensive research and testing, I’ve found that bioplastics represent both tremendous promise and certain limitations that are important to understand.

Bioplastics fall into several categories, each with distinct environmental profiles. PLA (polylactic acid), derived from cornstarch, is one of the most common. It looks and feels like conventional plastic but breaks down under industrial composting conditions. PHAs (polyhydroxyalkanoates) are produced by microorganisms and decompose in home compost bins and even marine environments. Then there are cellulose-based films, which offer excellent transparency and breathability.

In our packaging work, we’ve found bioplastics particularly valuable for applications requiring transparency, flexibility, and moisture barriers—areas where paper-based options often fall short. For example, we helped a clothing manufacturer switch to compostable poly mailers for their direct-to-consumer shipments, resulting in positive customer feedback and alignment with their sustainable brand image.

The environmental equation for bioplastics isn’t simple, however. Some require energy-intensive processing or compete with food production. Proper disposal remains challenging as many consumers don’t have access to industrial composting facilities. Through our client consultations, we emphasize the importance of clear labeling and consumer education.

Strategic Applications for Bioplastics in Packaging

Based on our research and client implementations, we’ve found bioplastics most effective when:

- Used selectively for specific applications where their properties are essential

- Combined with accurate disposal instructions to ensure proper end-of-life handling

- Sourced from non-food crop feedstocks like agricultural waste to avoid food competition

- Certified by independent bodies like TÜV Austria (OK Compost) or BPI to verify environmental claims

The bioplastic landscape continues to evolve rapidly. From my perspective in the industry, the next generation of these materials—incorporating algae, agricultural waste, and even captured carbon emissions—shows tremendous promise for truly sustainable plastic alternatives.

Get Premium Finishing For Your Designs At lvvpack

Looking for a reliable and nice price supplier? lvvack is your trusted partner for creating stunning designs that leave a lasting impression and add elegance and sophistication to your packaging. Contact us now to order.

Conclusion

The future of packaging is undeniably green, with innovative, sustainable materials offering viable alternatives to traditional options while meeting modern needs for protection, presentation, and planet-friendliness.